Vehicle Concept

In addition to being an attractive and comfortable light rail system for passengers, the Rhein-Neckar-Tram had to be technically reliable and as little susceptible to wear as possible. In addition, the RNT should be based on a tried-and-tested basic design that has already proven itself under difficult operating conditions: The Škoda Artic design.

General Conditions and Requirements

- Metre gauge (1000 mm)

- Railway and tram operation (up to 80 km/h)

- Vehicle width 2.40 m

- Length of existing platforms

- Double traction capability (in line operation and towing scenario)

- Narrow track curves with a 15 m radius

- Long and steep ramps

- Permissible maximum axle and total loads for tracks and structures

- Redundant design of drive and brake system for high reliability

- Solid construction and favourable wear properties on the track and vehicle

In addition, requirements for the railway that have developed considerably in the years since the last new acquisition were also taken into account: for example, passive safety, i.e. the stability of the car bodies and collision protection. Due to higher demands on customer comfort and operational flexibility, the new trains can be better air-conditioned, for example, and can travel up to 1.5 kilometres without overhead lines.

All of this has a direct impact on the vehicle design, the overall vehicle length, the number and length of the individual vehicle body segments and the number, design and position of the running gear. In addition, framework conditions and requirements have an impact on the vehicle weight and therefore also on the dimensioning of the braking systems. In addition, there are operational requirements to ensure reliable passenger transport and to enable cost-effective repair and maintenance.

Conclusions

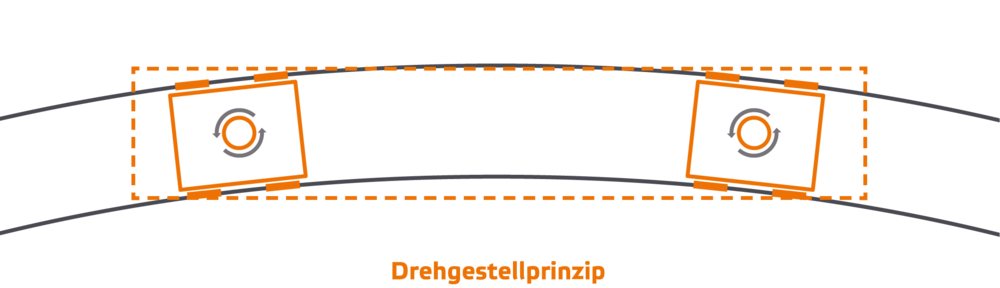

Only with a bogie concept can the higher vehicle weight be harmonised with the framework conditions of the infrastructure. These bogies, which can move and swivel freely in relation to the vehicle body, enable particularly good ride comfort thanks to a smooth, even and jerk-free ride on bends. In addition, a bogie means less wear, higher vehicle availability, shorter workshop visits and fewer track construction sites in the long term.

However, the tight curve radii require the bogies to move relatively far into the passenger compartment in track curves, the width of which is also limited. To enable this radius of movement, the floor in the bogie area had to be raised. Passengers have to overcome the difference in height using steps or a ramp with a narrow centre aisle. For reasons of accessibility and as a result of the dialogue process, RNT opted for ramps.

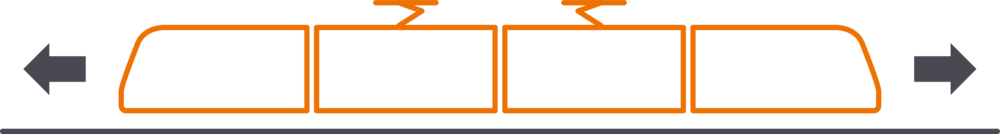

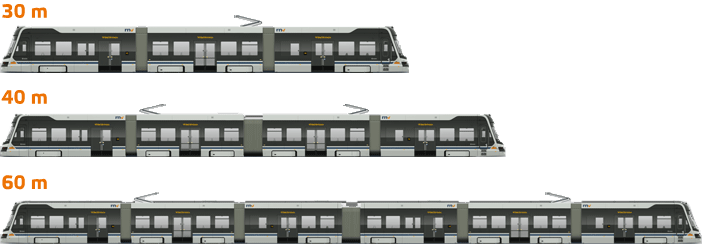

Modular Train Formation

The new RNT vehicles are supplied in three length classes of 30, 40 and 60 metres. A modular vehicle concept has been implemented. This combines the greatest possible flexibility and adaptability to future developments and requirements with a significant optimisation of workshop and maintenance processes. As a result, fewer vehicles will break down in the event of damage and more will be available for the route.

Technically, a vehicle in the 40-metre class consists of two identical and independently drivable 20-metre sub-vehicles that are permanently coupled "back-to-back" and are continuously accessible. Similarly, the 60-metre vehicles consist of two coupled and continuously accessible 30-metre sub-vehicles. These can be dismantled into the shorter sub-vehicles in the workshop using a quick disconnection point.

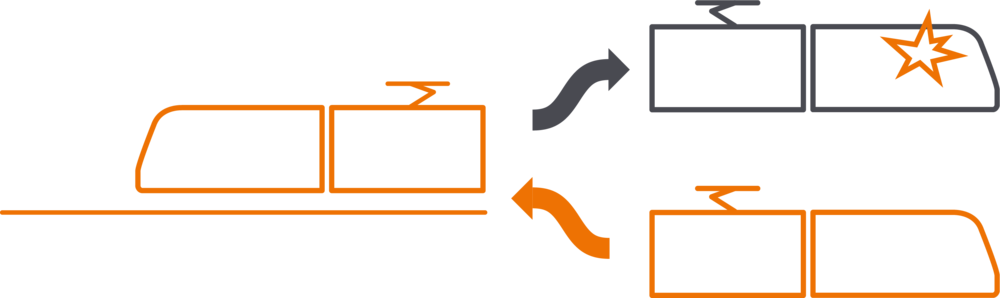

Until now, rnv's existing 40-metre vehicles could only be treated as a single unit. If, for example, there is a minor maintenance or repair requirement at one end of the vehicle, the entire vehicle has to go to the workshop and is not available for passenger services during this time, although large parts of the vehicle would be fully operational.

With the new 20 and 30 metre long sections of the RNT, which together form a 40 and 60 metre class vehicle and are only used in passenger service when coupled together in this way, only the vehicle parts in need of repair would have to be sent to the workshop. The unaffected vehicle halves can be flexibly reassembled and then sent straight back onto the route.

Standardised Procurement of Bidirectional Vehicles

What is new - at least for the Ludwigshafen transport area - is that the Rhein-Neckar-Tram is a bidirectional vehicle.

Such vehicles with fully-fledged driver's cabs at both ends and with doors on both sides have already been in use for years on the rnv railway line 5 and in Heidelberg. With the RNT, bidirectional vehicles will become standard in the entire rnv transport area.

There are also economic advantages to the standardised procurement of bidirectional vehicles due to the larger number of similar vehicles. In addition, the use of bidirectional vehicles leads to less wear and tear, as the tracks and wheels are worn more evenly with appropriate use.

A fully-fledged driver's workplace at the rear also helps to fulfil the legally prescribed crash standards. These also require a full structural extension in the rear of the vehicle, as in the front. A simplified design of the rear of the vehicle, as in existing vehicles, is no longer permitted.

Powerful and Efficient Drives and Recovery of Braking Energy

The new Rhein-Neckar-Tram has efficient and powerful drives. These enable good driving dynamics and therefore fast progress in traffic.

To ensure optimum progress, all axles are driven. The energy generated during braking is stored in high-performance capacitors so that it can be used again directly during the next acceleration process, thereby reducing power consumption. This resource-saving technology is the basis for being able to run individual short sections without overhead lines in the future. The batteries required for this are taken into account in the design of the vehicle body and the vehicle electronics and can be retrofitted if necessary.